Model T of mass housing

The Model T of mass housing - moladi

The mass production techniques Henry Ford championed in the automotive industry, lean production and lean assembly, is what our CEO, Hennie Botes is focused on implementing in affordable mass housing in order to eliminate waste, speed up production resulting in cost reduction

moladi - Mass Housing Construction System

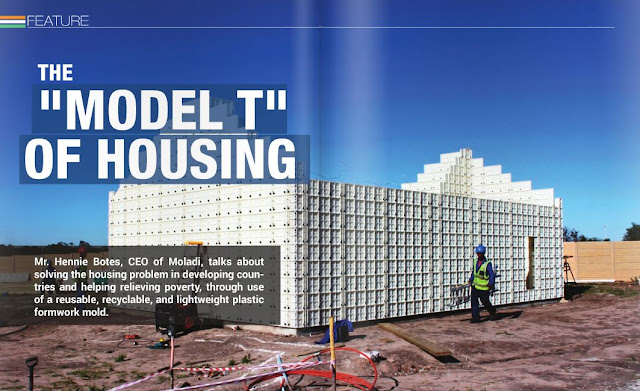

Mr Hennie Botes, CEO of moladi, talks about solving the housing problem in developing countries and helping relieving poverty, through the use of a reusable, recyclable and lightweight plastic formwork mold.

moladi

approaches building construction as a "Production Line" similar to

that of the automotive industry. "One of the important principles under

a lean production paradigm is termed "lean assembly". This refers to

simplifying the process of assembly through industrialisation,

modularisations, standardisation, and continuous flow processes. The

reduction of operations required for a production process means less

chance of the occurrence of errors, waste and rework. This follows

from the same logic that the fewer the number of operations, the

higher the quality of the product and a predictive timeline,

resulting in cost savings."

The application of the moladi technology is

not dependant on skilled labour and is especially suited for

repetitive housing schemes to enable community involvement as well as

the individual to obtain their own home. The injection moulded formwork is lightweight and robust, allowing

for easy transportation and speedy assembly. The precision components

are interlocking to produce easy to handle panels which can be re-used

50 times; making the technology cost effective due to this repetitive

application scheme. moladi provides for a realistic modern

alternative in overcoming the widespread misuse of scarce materials,

particularly timber, by introducing a system that combines moladi with

other indigenous materials, which are suitable for easy handling.

It all comes down to efficiency of producing a cost effective, socially acceptable wall for people (knock test), then fixing all the other components, like door, windows, roof, ceiling, bathroom fixtures etc., onto the "chassis" (the wall). So in reality, who can produce a wall on a stand the quickest, and millions of them? We simply use a cost per square meter of a wall (chassis) on a foundation (in position), ready for "assembly" as a yardstick of efficiency. This is method compares "Apples to Apples"?

It all comes down to efficiency of producing a cost effective, socially acceptable wall for people (knock test), then fixing all the other components, like door, windows, roof, ceiling, bathroom fixtures etc., onto the "chassis" (the wall). So in reality, who can produce a wall on a stand the quickest, and millions of them? We simply use a cost per square meter of a wall (chassis) on a foundation (in position), ready for "assembly" as a yardstick of efficiency. This is method compares "Apples to Apples"?

|

| moladi - MODEL T |

|

| Affordable Housing |

Reduce Cost of Housing Construction

The impact of appropriate technology becomes particularly noticeable

when innovative solutions are used and promoted by social entrepreneurs

who put social impact at the heart of their business. The combination of

low-cost technology and social entrepreneurship can have far-reaching

implications for thousands of lives. Creating jobs, stimulating

ownership confidence and the spirit of innovation – this is what social

businesses are looking for

For more information on moladi - Visit www.moladi.com

Keywords - mass housing, Model T, moladi, housing, production, lean, Henry Ford, Hennie Botes, assembly line, technology, eliminate waste, speed, production, cost reduction, #moladi, construction, material, plastic formwork, formwork, system, technology